Oil Free Screw Blower

UCBS Series

- Industries: Sewage Treatment Textile?? Food & Beverage Medical Transportation Petrochemical Industry Packaging Paper & Printing Pharmaceutical Power Industry

Description

UNITED new generation UCBS series oil-free screw blower manufactured with advanced screw moulded line technology. Through the working principle of internal compression, significantly improved the compression efficiency. Its actual energy-saving rate is up to 35% compared with the traditional roots blower's external compression. As a tremendous energy-saving positive displacement blower, it widely used in sewage aeration, gas-water backflush, oxidation desulphurization, fluidization/homogenization technology, pneumatic conveying, printing and other industries that require of high efficiency, energy saving, low noise, high-pressure blower, to perform roles of drying, dust removal, fermentation, evaporation distillation, pneumatic conveying.

High-Quality Screw Blower

At present, Roots blower is still widely used in all walks of life. It was a reliable and straightforward design solved problems in various fields of process application and made an enormous contribution to industrial development. However, Roots blower's inherent characteristics of high energy consumption and high noise are incompatible with today's user's requirement, in which the whole society pursues green environmental protection, energy conservation and emission reduction. In contrast, the oil-free screw compression technology brings efficient and ecological protection blower products that will replace outdated and inefficient Roots blower technology.

The oil-free screw compressor technology has fully testified by the market and have applied to the lower pressure blowers. The design and manufacture experience of oil-free screw compressor also make the oil-free screw blower stable and reliable, developed from oil-free screw compressor technology, the screw blower has three outstanding and attractive characteristics: high efficiency, low noise and oil-free air.

Product Features

·?????? Embracing world-advanced high efficiency moulded lines, developed stable high-efficiency air compressor.

·?????? The advanced coating technology makes the air end clearance smaller, improves the volume efficiency, and also effectively protects the air end for longer life.

·?????? The selected world-famous FAG bearing guarantees reliability.

·?????? Adopting National Standard level 5 precision synchronous gear and the drive gear, to ensure reliability and prolong the service life.

·?????? Labyrinth seal and spiral seal assemblies ensure oil-free air up to Class Zero.

·?????? Extraordinary lubrication and oil drainage channels ensure adequate lubrication and cooling of bearings and gears while improving the efficiency of the compression.

Low Noise

There is no internal compression of roots blower, which results in the reverse filling of higher-pressure air in the pipe network into the compression chamber during exhaust, forming air impact, producing high low-frequency air noise and great vibration of equipment. The screw blower has internal compression, and its compression chamber exhaust pressure is close to the pipe network pressure, smooth exhaust, significantly reducing the vibration and noise of the equipment. The noise of the screw blower concentrated in the high-frequency part, and this part of the noise can be dealt with by silencer and noise reduction measures. Thus, the noise of the whole screw blower is 30dB (A) lower than that of the Roots blower.

After analyzing the frequency spectrum of the sound source, the professional design of customized intake and exhaust silencers dramatically reduces the noise transmission of oil-free screw compressors to the external environment. The whole oil-free screw blower wholly sealed with an acoustic enclosure. The air inlet processed by a specially designed noise-reducing air inlet and then enters the internal chambers. The transmission of noise from internal to external minimized.

Inside the exhaust silencer, there is no asbestos, PE cotton and other sound-absorbing materials. The sound elimination achieved through acoustic design, therefore there is no secondary pollution to the air, to ensure the requirement for clean air.

?

·?????? PLC intelligent control, 6"colour LCD touch screen display.

·?????? User-friendly operating system.

·?????? The controller features the start-stop control, frequency conversion control (Variable frequency version), exhaust pressure real-time monitoring, exhaust temperature, lubricant oil pressure and temperature, the maintenance time, error early warning, error recording and others.

·?????? RS485 connection, linkage control and remote control. Variable frequency version supports the signal control of Dissolved Oxygen concentration (DO).

·?????? Standard wireless internet module allows remote access from PC, Pad, smartphone, able to check running status at any time from anywhere.

High Efficiency

Compared with the traditional Roots blower, UCBS oil-free screw blower has higher efficiency from the technical principle.

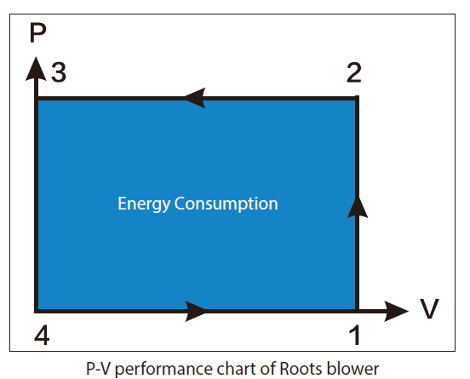

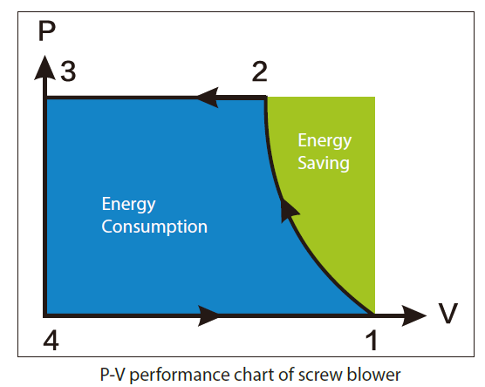

See below P-V performance chart of Roots blower and screw blower for details.

?

4 → 1 Inspiratory process. As the Roots' rotor rotates, the air inhaled in until the intake vent is closed.

1 → 2 External compression process. It can break down into two processes. The Roots rotor continues to rotate, the volume of the enclosed space does not change, so there is no internal compression.

Until the enclosed space suddenly exposed to the outlet vent, this part of the air pressure rises as the pipe network compressed.

2 → 3 Exhaust process. As roots rotor continues to rotate, the compressed air releases to the piping network.

?

UCBS Oil-Free Screw Blower Can Save Up to Energy Compared to Roots Blower

?4 → 1 Inspiratory process. As the screw rotor rotates, the volume of the

spiral groove gradually increases, and the air inhaled into the blower until

the intake vent is closed.

1 → 2 Internal compression process. The intake vent ha closed, and the exhaust vent has not opened yet. Due to the spiral design, the spiral movement makes the volume of the closed spiral groove smaller and smaller, resulting in internal compression and pressure rise.

2 → 3 Exhaust process. As the rotor continues to rotate, the exhaust vent opens, and the compressed air discharged from the blower.

?

Under the same condition of air volume and pressure, screw blower consumes much less power. In the figure, the green portion shows the energy saved. Compared with the traditional Roots blower, the screw blower saved 35% energy. The higher the pressure, the more significant the energy savings, with average energy saving achievement of 20%. Plus, the precision design and manufacture, intelligent control and variable frequency drive, compared with Roots blower, the energy efficiency of oil-free screw blower could reach 20%-50%.

UCBS oil-free screw blower is skid-mounted box type. Blower air end, motor, transmission, intake filter, intake and exhaust silencer, shock absorber, safety valve, exhaust check valve, starting cabinet, control system, frequency converter and sound insulation enclosure are all integrated and installed on the chassis. All units filled with lubricating oil complete testing before exit factory. It is not necessary to embed expansion bolts to the installation foundation, only requires a smooth and firm cement floor for installation. Connect the exhaust piping network, plug in the power cable, and the blower can be started and utilised.

It recommended installing a butterfly valve on the exhaust pipe of each blower to facilitate cutting off the connection with the piping network for equipment maintenance. It recommended that to use "Y" type tee instead of "T" type tee for the connection between the branch pipe and main pipe, which can reduce the loss of air pressure.

An optional outdoor rain protection kit allows user to install the blower system close to the point of use, such as next to a sump.

Application Fields:

Many fields of environmental protection and industrial production needed blowers producing low-pressure air. In the area of environmental protection, screw blower used to discharge wastewater and air. Both municipal sewage and enterprise sewage must be treated (including textile printing and dyeing, leather, medicine, chemical industry, papermaking, breeding, slaughtering and other fields) and up to standard before discharge into natural water or recycled. In the wastewater treatment process, one

of the critical links is the oxygen supply to biological treatment, which is the aeration process.

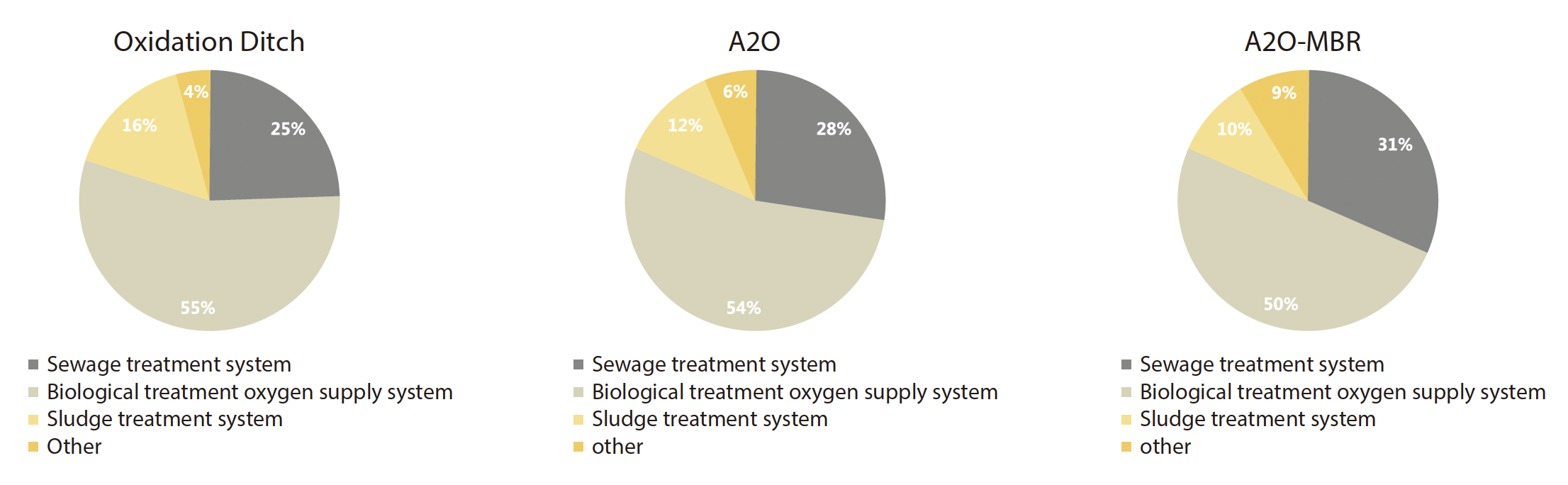

The energy consumption of biological treatment oxygen supply system accounts for 50% - 55% of the whole sewage treatment plant. There is much room to reduce the energy consumption in the oxygen supply biological treatment, and the selecting of the high-efficiency UNITED blower will bring the objective economic benefits directly.

Desulfurization and Denitrification

In thermal power plants, steel, glass, chemical and other factories, a large number of boilers are burning, and their flue gas contains a lot of sulfur, nitrate and other substances, which seriously pollutes the atmosphere. So, it is obligatory that flue gas to received desulfurization and denitrification treatment before discharging to the atmosphere. In desulfurization and denitrification facilities, the high-pressure blower required for the oxidation process.

Fermentation, Pneumatic Conveying, Air Knife, Texturing

High-efficiency oil-free screw blowers can find using in bioengineering, pharmaceutical, cement, steel, power generation, grain processing, textile and more other industries, which have made a significant contribution to the consumption reduction per unit output value.

Technical Parameters

Oil-Free Screw Blower UCBS Series | ||||||||

Rated power (kw) | 18 | 22 | 30 | 37 | 45 | 55 | 75 | |

UCBS 180 | Pressure rise (kPa) | Flow (m3/min) | ||||||

50 | 14 | 22 | 29 | 32 | 33 | |||

70 | 14 | 22 | 27 | 32 | 38 | |||

90 | 15 | 21 | 31 | 34 | ||||

110 | 15 | 26 | 30 | 41 | ||||

130 | 14 | 20 | 26 | 35 | ||||

150 | 14 | 20 | 30 | |||||

UCBS220 | Rated power (kw) | 55 | 75 | 90 | 110 | 132 | 160 | 185 |

Pressure rise (kPa) | Flow (m3/min) | |||||||

50 | 62 | 74 | 90 | 110 | 110 | |||

70 | 51 | 71 | 71 | 80 | 96 | |||

90 | 40 | 54 | 65 | 70 | 80 | 100 | ||

110 | 44 | 54 | 70 | 73 | 88 | 100 | ||

130 | 44 | 60 | 69 | 78 | 90 | |||

150 | 38 | 48 | 60 | 68 | 80 | |||

Remarks: | ||||||||

Working Condition: 20℃,1.033kgf/c㎡,65%RH | ||||||||

Error range: +/- 5% | ||||||||

According to the actual conditions, the above data are subject to change without prior notice and can communicate with the manufacturer for consultation. | ||||||||

?

Share:

Related Product

Magnetic Suspension High-Speed Turbo Blower

UCMB Series

Air Suspension Bearing Centrifugal Blower

UCTB Series

Oil Free Screw Blower

UCBS Series